F180 Black silicon carbide for application workpiece surface treatment grinding and polishing

Black Silicon Carbide is produces in electrical internal resistance furnaces from high purity silica sands petroleum coke,its combination of being very hard and sharp makes it a very aggressive abrasive.

PHYSICAL PROPERTIES

| Specific Weight | 3.95 g/ cm3 |

| Mohs Hardness | 9.15 |

| Maximum service temperature | 1900℃ |

| Melting Point | 2250℃ |

TYPICAL CHEMICAL ANALISIS [%]

| SiC | Fe2O3 | F.C | F.Si | SiO2 | LOI |

| 98.0-99.5 | ≤0.10 | ≤0.20 | ≤0.20 | ≤0.50 | < 0.05 |

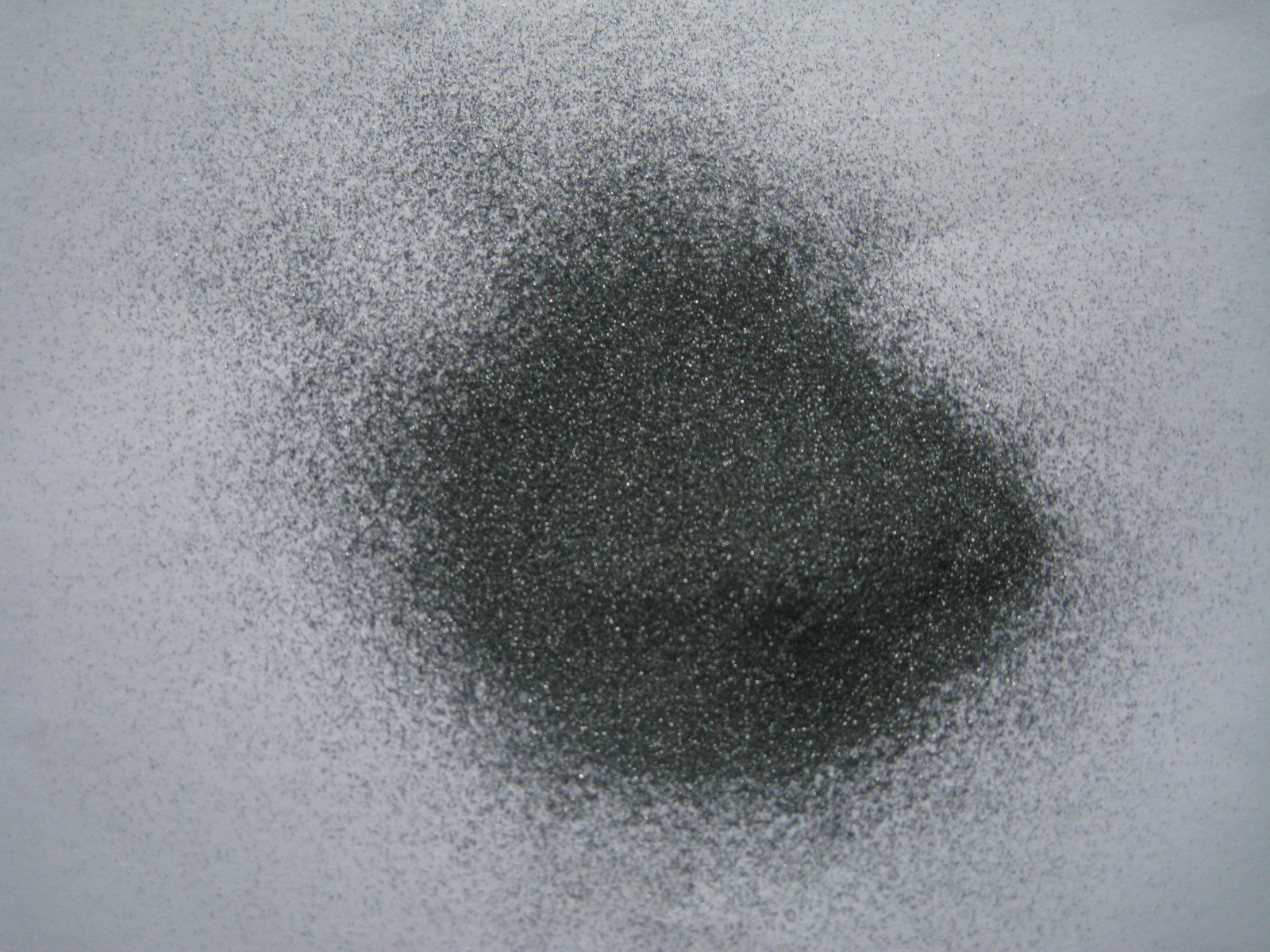

PPARTICLE SIZE DISTRIBUTION

| Size | +125um | +90um | +75um | +75+63um | -53um |

| F180 | 0 | ≤15% | * | ≥40% | * |

Mainly Applications

-Bonded Abrasives and Coated abrasives

-Blasting,surface Treatment,Rust Removal

-Wet and dry blast media,grinding and polishing etc

-Floor/Wall laminates,Wear-resistant

-Ceramic products: Ceramic and Tiles,Ceramic filter plate,ceramic membrane etc

-Teflon painting etc

– Heat insulating material

-Grinding wheels,Cup wheels,Whetstone,polishing pads etc

-Used for crucibles, parts for kiln burning, mechanical seals, and parts materials to produce semiconductors

نقد و بررسیها

هیچ دیدگاهی برای این محصول نوشته نشده است.